The Trust Crisis in Peer-to-Peer Production

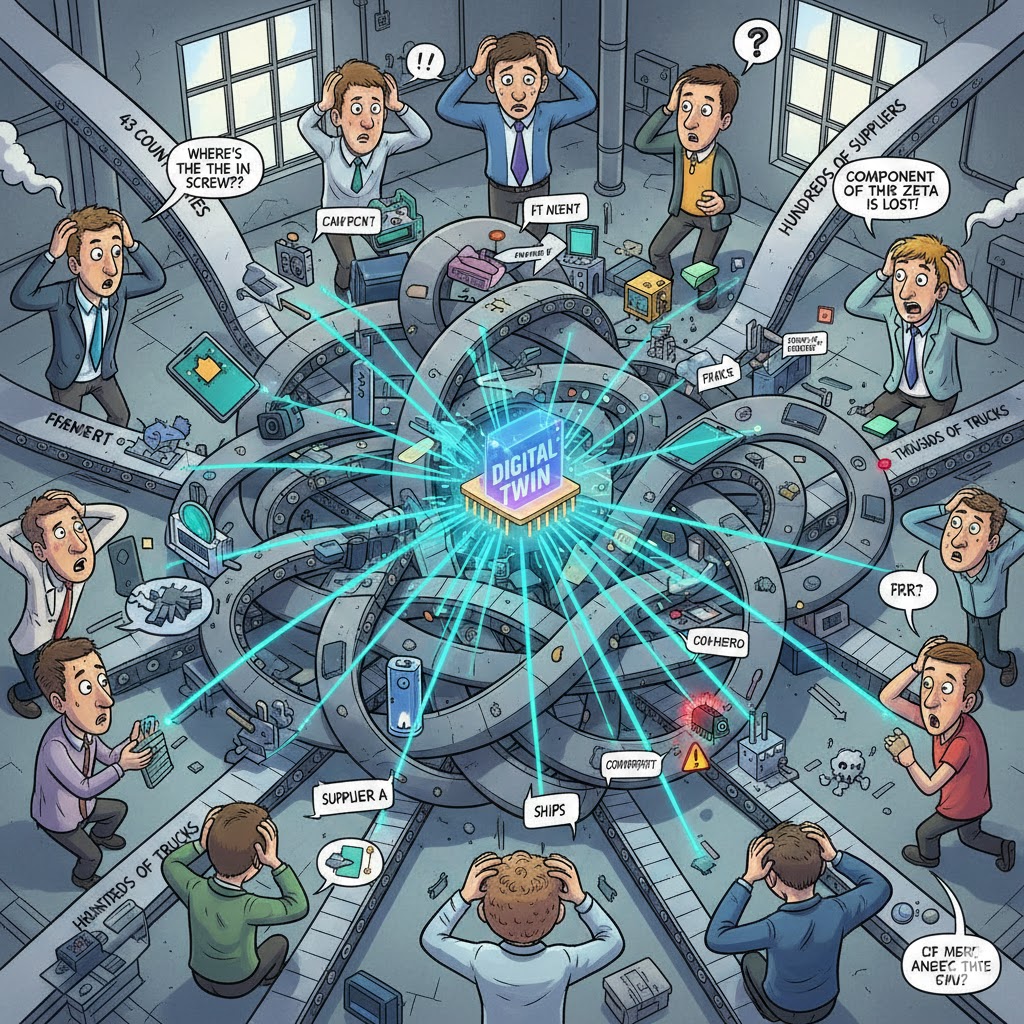

Whereas traditional manufacturing has typically been carried out through tightly controlled environments such as factories, this is not the case with decentralised manufacturing (DecM). The DecM environment is more open than ever before, allowing anyone to upload designs for production anywhere. The DecM environment allows anyone to request and receive a physical object from a global disperse production network (DPN).

Although DecM provides unprecedented opportunities for global collaboration and innovation, it also poses challenges such as trust between parties, verification of design quality, and preventing design forgery. Blockchain technology, with its inherent trust architecture, allows companies like 3DOS and others to create secure solutions using NFTs to track and protect design rights, facilitating the establishment of peer-to-peer manufacturing networks. Without a sufficient level of trust through cryptographic verification, DPNs enable fraudulent activities to take place through design modifications or substitutions of lower quality materials.

Blockchain as the Foundation for Manufacturing Provenance

The blockchain allows you to track your product or service from A to Z via a permanent and verifiable ledger of all transactions since its creation, from start to finish. It provides a transparent and traceable system for verifying the manufacturer and the quality of products manufactured within the supply chain using decentralised manufacturing systems. Smart contracts, through Ethereum and other similar systems, enable companies to enforce payment and quality terms automatically without going through third parties (intermediaries). The use of cryptography in Blockchain technology proves that data can only be recorded once, providing a common point of reference (Single Source of Truth) to all locations (nodes) within the manufacturing supply chain.

NFTs as Digital Twins for Industrial Assets

Using NFTs, each product can be tracked throughout production via digital twins. As products are manufactured, the information concerning design files, material specifications, and process conditions becomes tokenized as part of an NFT. If the finished product design file is then uploaded to an online community, such as 3DOS, it is converted to an NFT and stored on the blockchain, where it serves as proof of authenticity and ownership. Every time the product design is manufactured, the creator receives a royalty. This relationship between the real-world item and the digital file representing it is referred to in academia as a 'tamper proof digital twin', as they are updated in sync with each other over the life of the product.

Real-World Implementation: The 3DOS Case Study

The 3DOS platform is built on NFT technology and allows users to upload their ideas online, receive payments for those ideas, and have products manufactured globally on demand. 3DOS demonstrates how blockchain technology (specifically, the use of crypto within the supply chain) can solve real-world issues related to the manufacturing process. For instance, through the use of smart contracts, designers may protect their intellectual property, manufacturers may have access to a worldwide marketplace of verified design files, and consumers can track the entire progression of an item from its original digital file to its final physical form. 3DOS uses Sui's blockchain and Walrus's decentralised storage to store design files with unalterable metadata. In doing so, 3DOS protects creators by ensuring that they own their designs and retain the right to royalties for all future sales. Overall, the 3DOS platform illustrates how blockchain technology has the potential to completely alter the way manufacturing is conducted by taking the traditional centralised authority model and decentralising it.

Academic Foundations: Digital Twins Meet Cryptography

Some ways NFTs have contributed to the evolution of digital twin technology in industry include their ability to monetize their intellectual property, improve traceability and enhance asset management and transparency. Researchers have studied dynamic and composable NFT models that will change over time with the manufacturing process creating living records of a company's production history. Digital twins created with blockchain provide an immutable and transparent record of the information recorded, thus creating an excellent foundation for the management of industrial assets. Through this body of work, academic studies effectively demonstrate how cryptography can provide long-term solutions to the many challenges faced when it comes to maintaining the integrity of the supply chain and protecting intellectual property.

How Blockchain Solves the Counterfeit Manufacturing Problem

With Provenance blockchain, users can remain informed about where data originates from, how it was created, modified or transmitted, and how long it has been held by various outlets. Furthermore, due to its ability to provide verifiable computations of data, Provenance also allows users to trust that their information is authentic and secure. These attributes are particularly beneficial for the prevention of counterfeit components making their way into a product's supply chain within a decentralised ecosystem; all parts within that chain contain a unique cryptographic certificate attesting to their legitimacy, which can be easily verified by any party accessing that chain of provenance. In addition, Provenance allows Smart Contracts to automatically confirm the compatibility of a material with a specific requirement, that all processes carried out upon that material adhered to pre-defined protocols, and that the finished product was manufactured according to its original design without the requirement of a Centralized Authority or Third Party Trust.

Beyond Trust: How Crypto Economic Incentives Align Production

The real innovation is how bitcoin mechanisms make sure that economic incentives are the same throughout dispersed production networks. The 3DOS coin rewards and encourages people to actively participate in the decentralised network of 3D printers. Designers get tokens when their designs are made, producers get paid for work that has been checked for quality, and validators get paid for keeping the network safe. This crypto-economic approach sets quality standards that are enforced by reputation and revenue, which are directly linked to performance that is confirmed by the blockchain. This creates a system where people don't have to trust each other because they have an economic reason to be honest.

Challenges and the Future of Decentralized Manufacturing

Blockchain technology makes operations safer and more efficient by making it easier to trace transactions. Smart contracts also speed up transactions and save administrative costs. But there are still problems with implementation, such as limits on scale, the requirement to integrate with existing manufacturing systems, and the necessity for standardised protocols across industries. Research is centred on creating distributed, tamper-proof collaboration platforms that enable traceable and reliable data sharing, safeguard intellectual property rights, and support decentralised governance. Blockchain-enabled manufacturing has the potential to make production more democratic, cut down on waste through on-demand fabrication, and develop supply chains that are clear and fair to everyone involved.

NFTs, blockchain technology, and decentralised manufacturing coming together is more than just a technical update. It's a whole new way of thinking about how we make, sell, and check the quality of real items in a world that is becoming more digital. Crypto infrastructure adds the missing element of trust that allows peer-to-peer production possible on a large scale. This changes manufacturing from a centralised, expensive process into a distributed, open network where provenance is ensured and authenticity is built in.